Entry level Mooney Viscometer

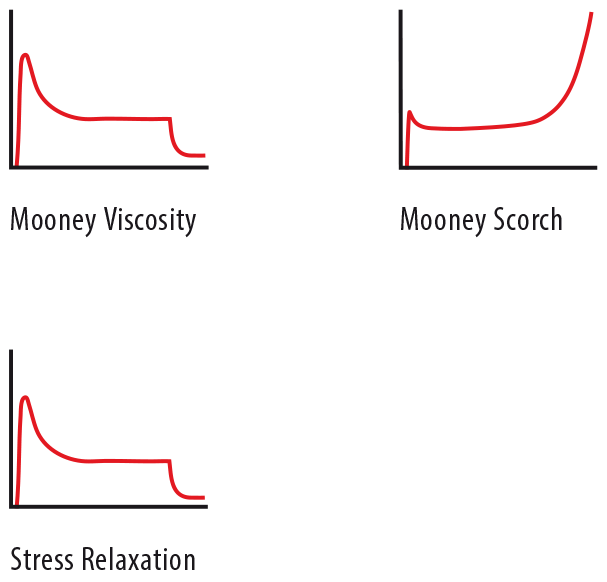

The MV 3000 Basic is a rotational shear viscometer according to Mooney for performing

– Viscosity tests (ML / MS 1+X)

– Stress Relaxation testing

– Mooney Scorch

– Delta Mooney testing

on polymers as well as rubber compounds for quality control, research and development applications.

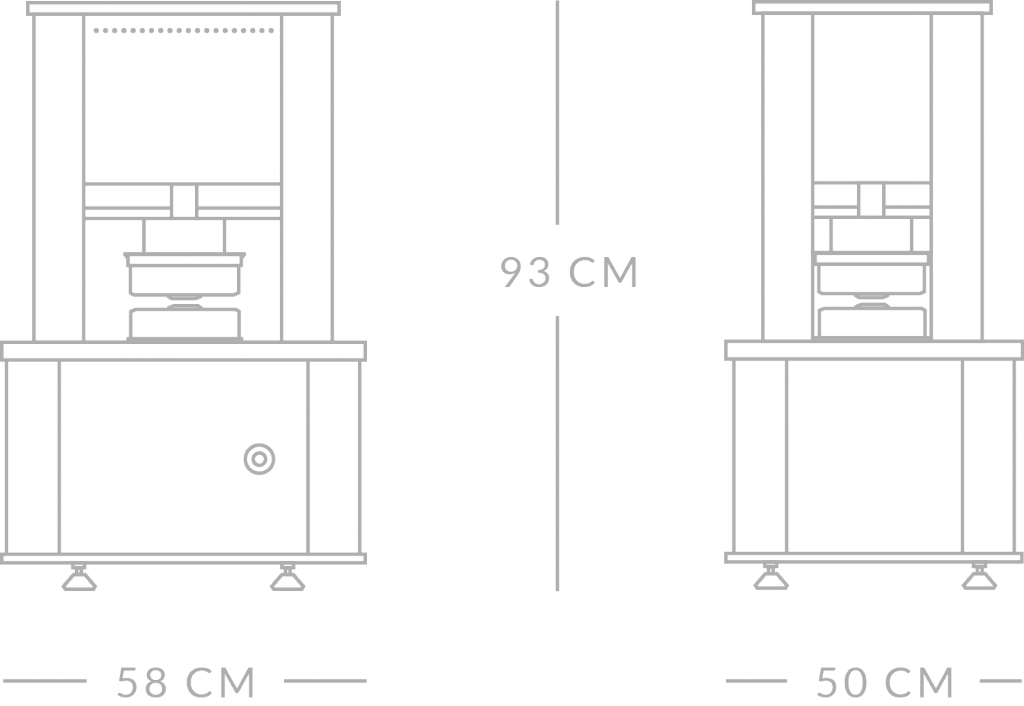

The MV 3000 Basic is supplied as a complete, ready-to-test instrument set including a personal computer, MonControl Software, cables, connectors and regulators as well as a standard set of tools and consumables.

Easy to use:

All test parameters are pre-programmed through the MonControl Software – the instrument is equipped with a single button for starting the test sequence.

Direct feedback:

An integrated multi-color LED status bar clearly displays the current machine state.

Rugged:

The compact and highly rigid frame is made from high strength aluminum. Along with direct-drive technology, this guarantees stable and accurate test results in every environment.