Industry standard Mooney Viscometer

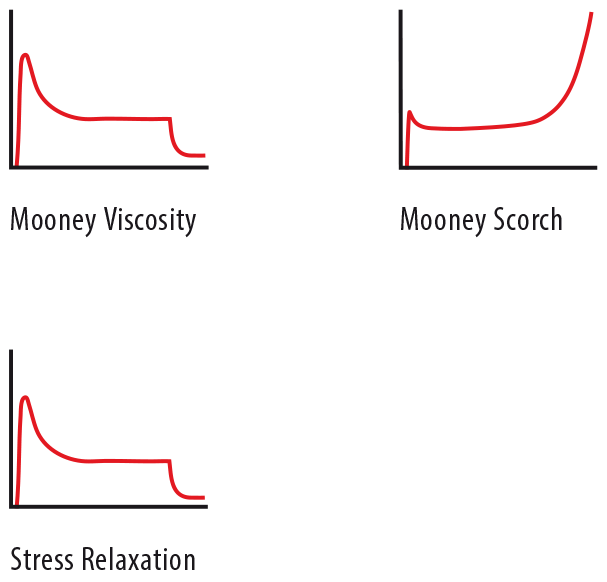

The Mooney Viscometer MV 3000 is the leading test instrument for measurement of viscosity, scorching and stress relaxation on polymers and rubber compounds.

The MV 3000 is suitable for quality control as well as research and development purposes with excellent repeatability and reproducibility due to its low-mass die design, direct heating and a unique direct drive design with snap-in mechanics.

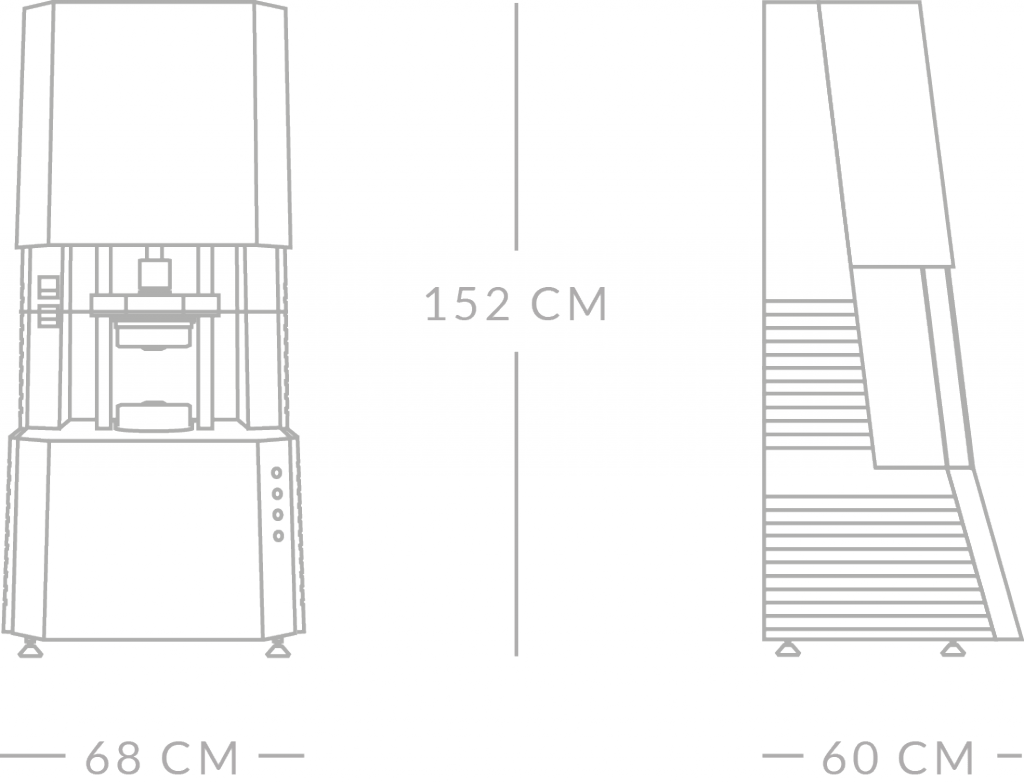

The massive aluminum frame of the MV 3000 with its 270° accessible die area allows easy sample loading while integrated rotor ejection simplifies rotor handling. Operation is made easy by 4 illuminated pushbuttons providing clear information about the machine state. A motorized safety shield separates the die area before the test sequence is started.

Die temperatures are accurately and precisely measured by calibrated probes and controlled with a precision of +/- 0.03 °C by heaters, dies and rotors with an extremely fast thermal response.

The MV 3000 is fitted with built-in software-controlled systems for automatic balancing and calibration, including a double dead-weight system to apply a defined torque of 100 Mooney units, ensuring the utmost data accuracy and eliminating the needs of any external tools or fixtures.