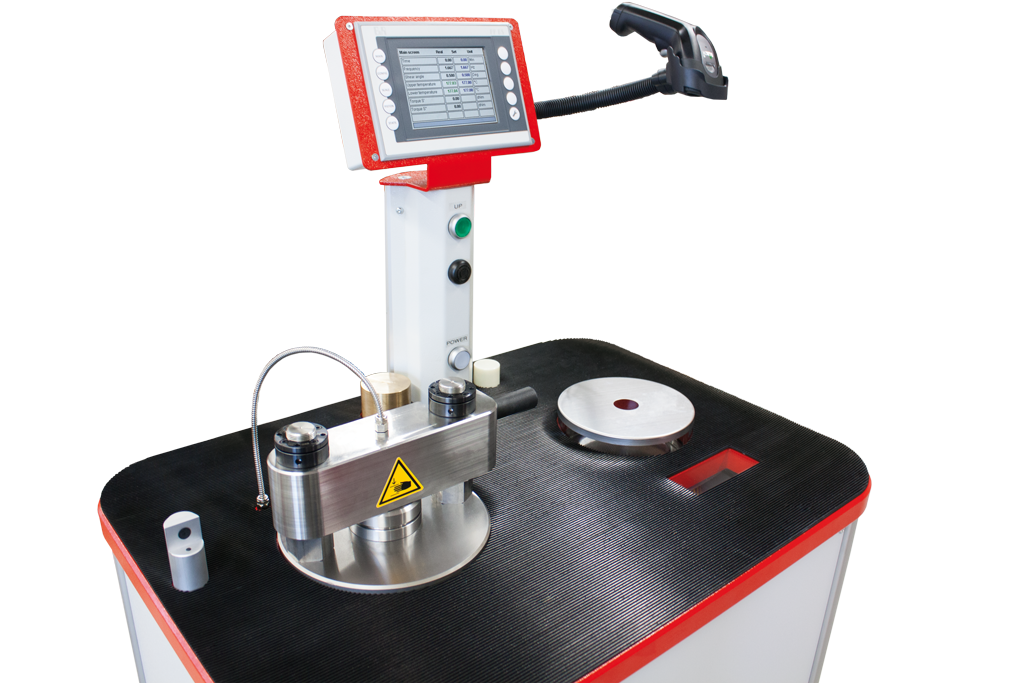

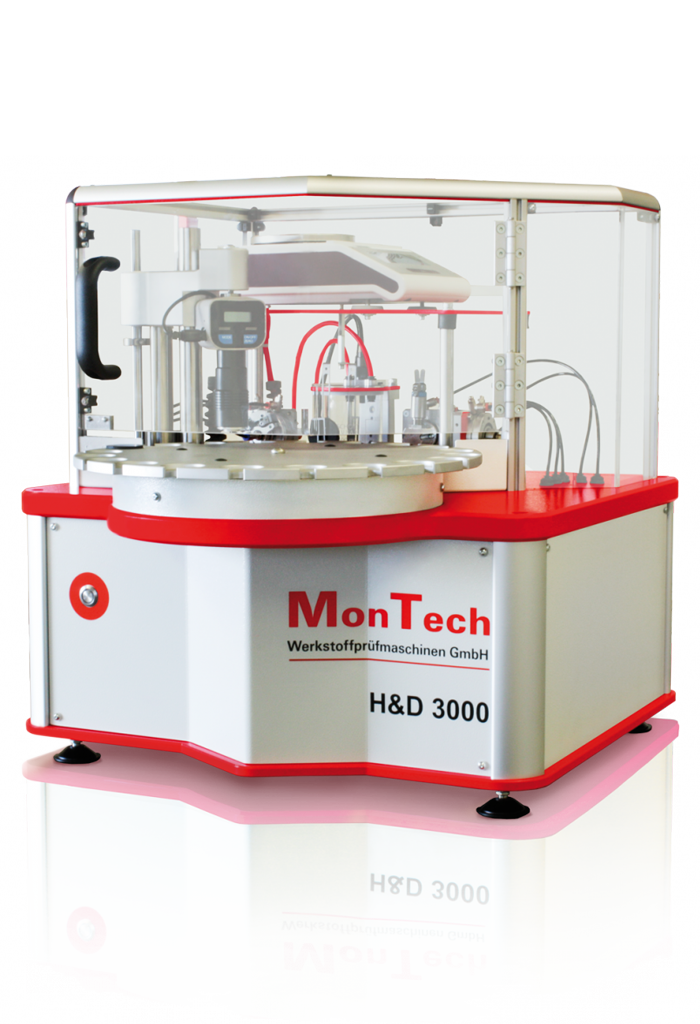

Automatic compression density tester for uncured rubber compounds and polymers

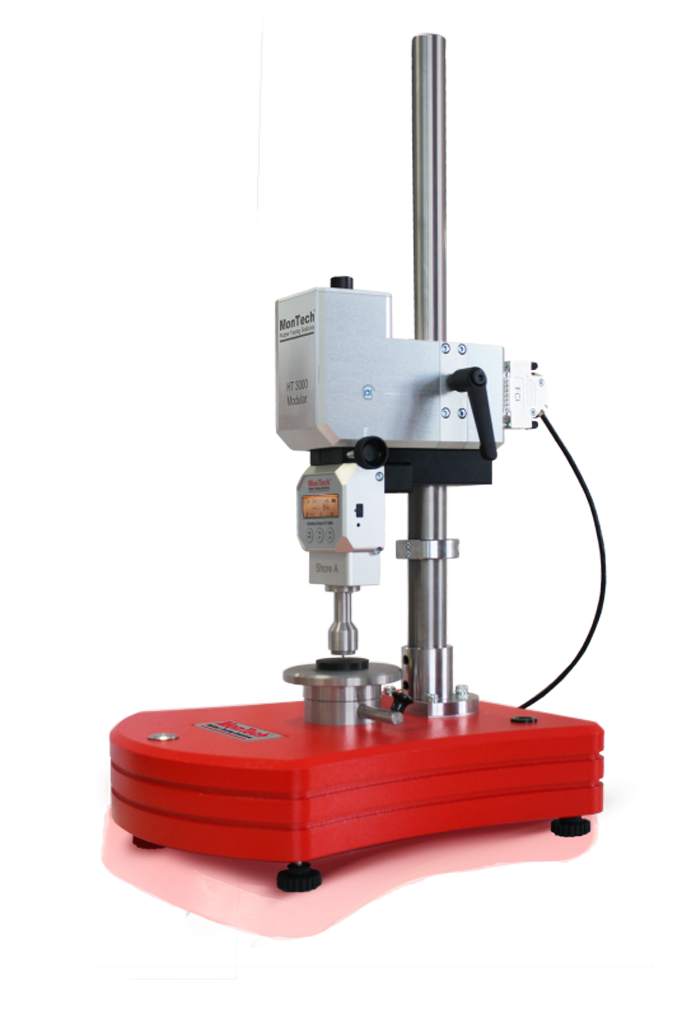

The RD 3000 is the simplest way to measure density and specific gravity of raw polymers, masterbatches and uncured rubber compound specimens of any geometry. Due to the extremely rugged instrument design, the RD 3000 is suited for laboratory and production environments. The true innovation of the RD 3000 is the way it measures density.

Typically, a strip of rubber is cut directly from the mill, identified at the control panel of the instrument and weighed. All air is compressed out of the sample in a compression cylinder and the volume of the material is taken. Once the density is automatically calculated, it is checked against tolerance limits and displayed along with Pass / Fail status.

A single test only takes about 20 seconds comprising the following steps

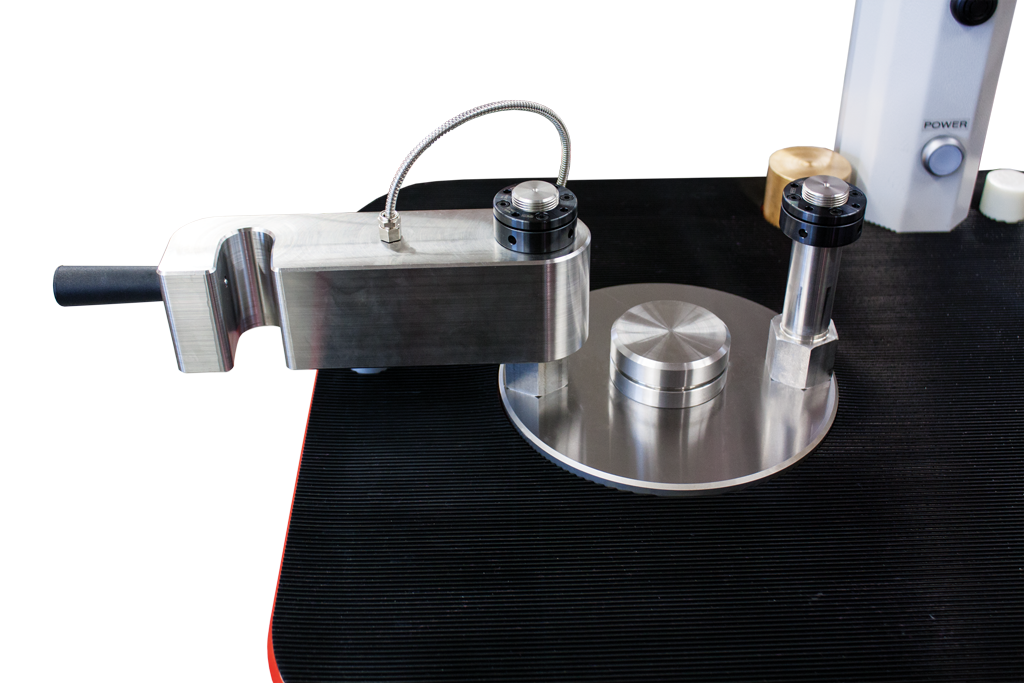

1 – Weighing

The sample is placed on the electronic balance which is integrated into the machine table. Therefore only stable weight readings will be accepted.

2 – Compression of the sample

The sample material is filled into the compression cylinder barrel and the compression of the material is started. Once the piston finally reaches a stable position in the compression process, all air is removed from the sample which means that the test sample is compressed to its specific volume.

3 – Volume determination

The sample volume is determined by calculating the difference between the piston stroke at an empty cylinder, and the piston position with the specific test material.

4 – Density calculation

The density of the sample is calculated automatically from the weight and the determined volume.

5 – Displaying of test results

The calculated sample density is displayed on the control panel or in the MonDevice software along with all other results in the test sequence. Single tests and test series results can also be directly printed by an optional built in printer.