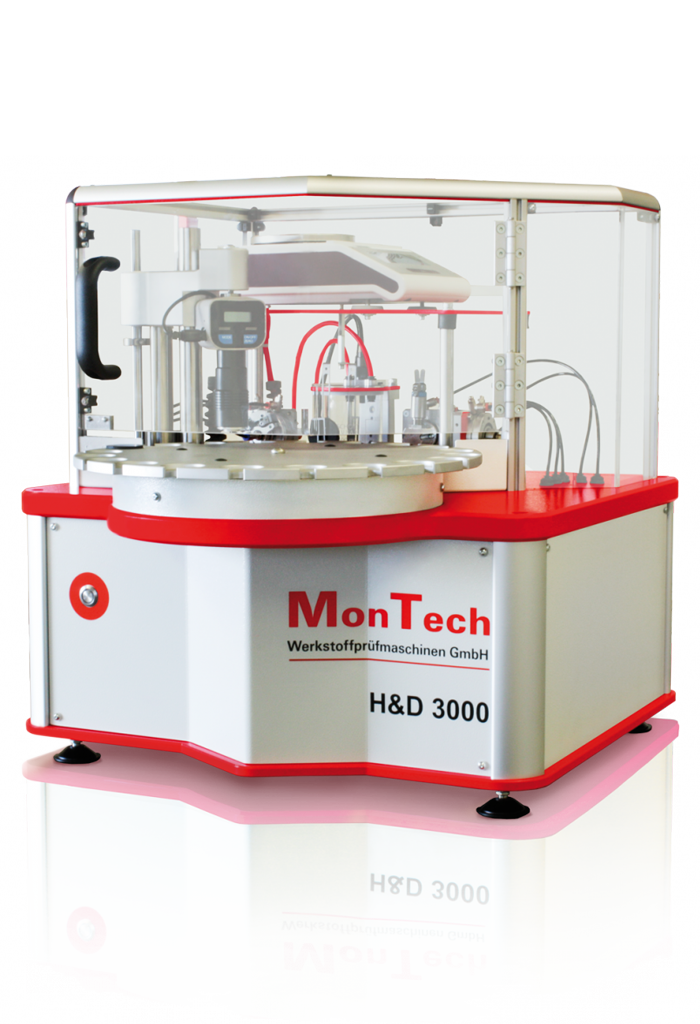

The H&D 3000 combines two important tests in a single instrument: Hardness and density are simultaneously measured on cured rubber discs. The instrument is completely software programmable for fully automated and unattended sample processing from a 20- position sequential rotary tray. Up to 5 individual Shore A hardness readings can be taken on each sample – afterwards the weight of the sample in air as well as in a temperature compensated immersion liquid is taken. Finally the reliable measured hardness and specific gravity test results, median and mean values as well as Pass/Fail status are automatically calculated and reported.

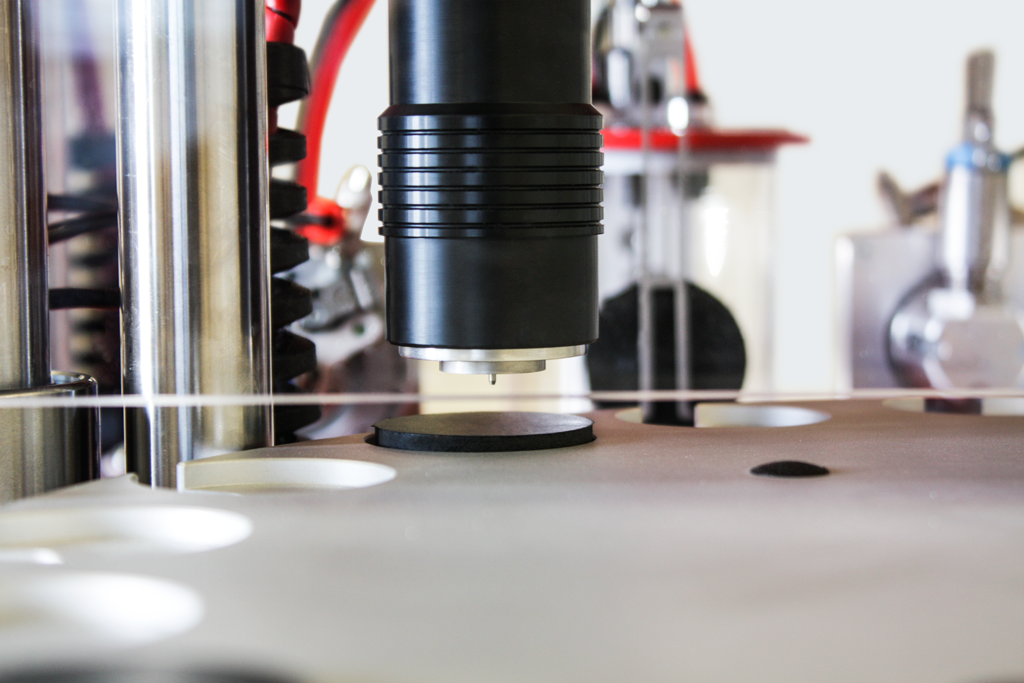

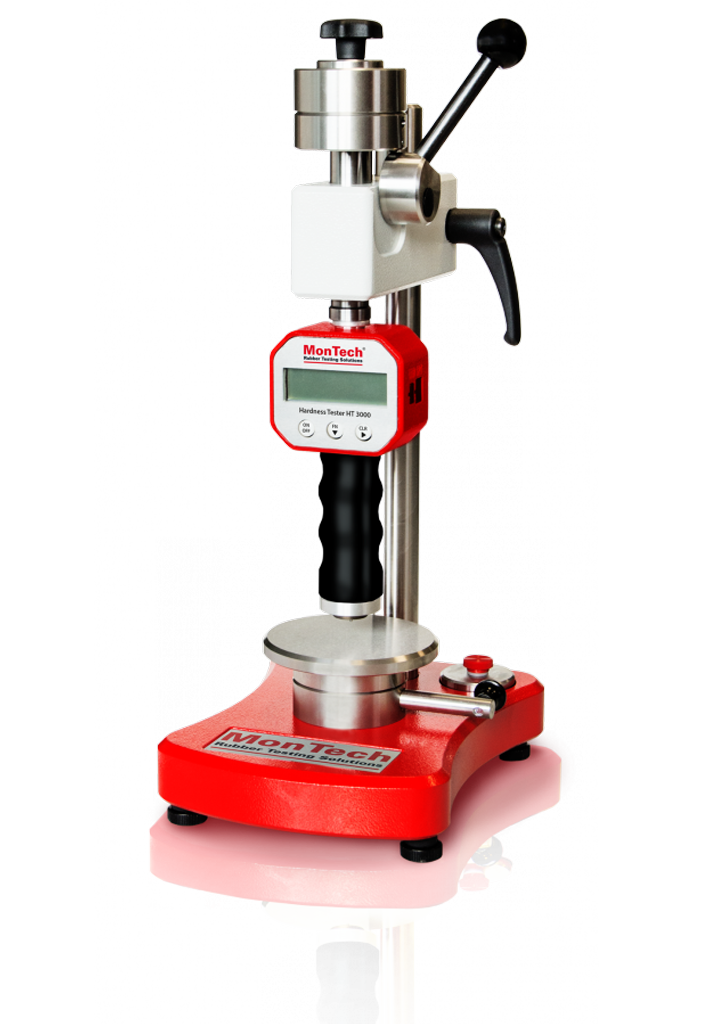

Hardness measuring head

The motorized and weight loaded hardness measuring unit featuring an integrated alignment and a digital measurement of the indentor displacement guarantees the highest precision hardness readings on up to 5 different test points per sample. Various types of hardness heads in accordance to different international standards such as Shore A, Shore D and IRHD are available. (multiple or interchangeable confi gurations available)

Precise sample handling

Stainless steel linear, rotational and multiposition electronic / pneumatic actuators provide safe and reliable handling of test samples. Actuators are mechanically separated into two groups: one for dry and one for wet samples to avoid any cross-contamination of the samples prior to weighing in the immersion liquid.

Integrated pump circuits

Ensure that the level of the density liquid in the dip tank is carefully controlled. After each density test, an adjustable amount of liquid is automatically renewed, keeping the density liquid fresh and in good condition. Also the pumps can be used to automatically fill, empty and change the density liquid in less than 20 seconds.

Endless rotary tray magazine

The rotary sample tray allows continuous operation of the machine, totally avoiding any

unproductive time. The testing area is separated by a supervised transparent safety door and covers all around the machine.