State of the art fatigue testing and lifecycle simulation

The FT 3000 is a high-end, direct linear drive fatigue tester of advanced design;

providing a full test which indicates material properties such flex cracking/crack growth test and tension fatigue test in accordance with: ISO 132, 6943, ASTM D 430-B , ASTM D 813, DIN 53 522 -1/2/3.

The instrument is designed for continuous operation in compound / material research & development laboratories as well as industrial applications like in-process quality control in rubber plants requiring repetitive testing of rubber samples to assess dynamic material performance properties.

Especially due to the unique advanced linear motor design, optional arbitrary waveform programming and CCD camera data acquisition system, the machine can easily be set-up and adapted to individual customer testing needs.

Precisely controlled thermal environment

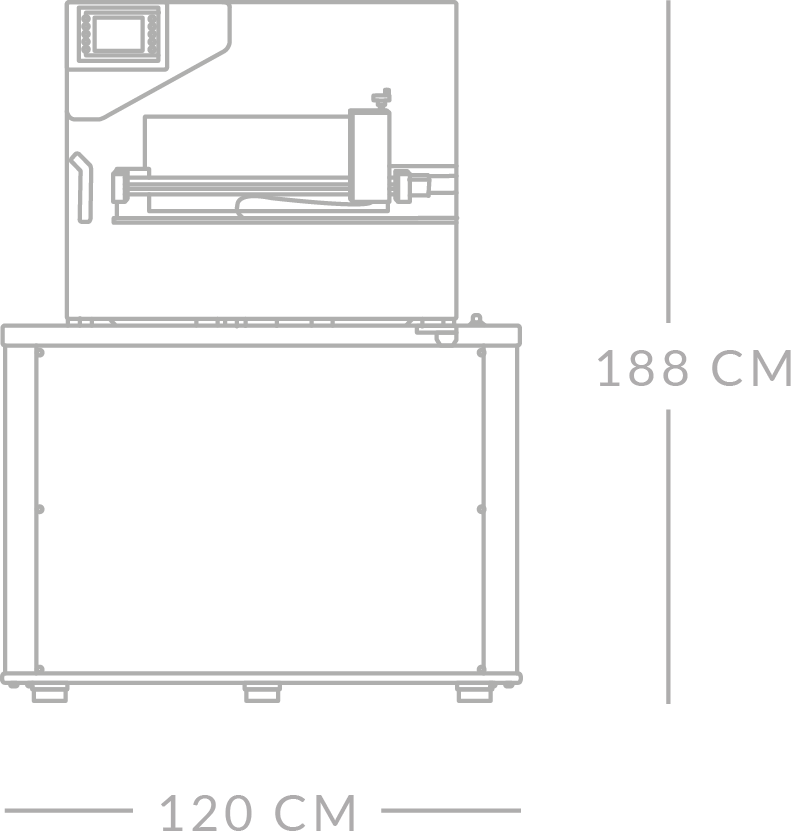

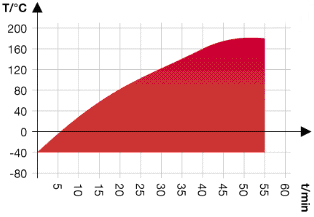

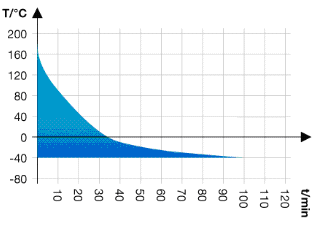

The sample holding system is located in a thermal chamber. This 120 liter heating and cooling chamber permits temperatures between -40 °C and +180°C, covering almost all possible application environments. Due to the unique triple stage closed loop chiller and compressor design, a superior temperature uniformity of +/-1°C is achieved with no gases or external media required for the cooling process.

Highest accuracy, rigidity and durability – guaranteed!

The direct drive, linear motor drive system with digital control and inline position measurement ensures extremely precise movements, low levels of noise and vibration, high durability and long lifetime. The instrument is fitted with a massive, deflection free stainless steel sample holder system. Optionally, samples can be inspected with a motorized camera CCD system for crack and crack–growth measurement – this system also includes the MonFT data acquisition software.

Instrument options

Camera CCD System (incl. MonFT software)

(Computer to be supplied locally according to specification)

For automated crack growth measurement and recording (De-Mattia) with variable camera setup for through hole or surface measurement, automated lateral camera travel as well as integrated LED light system.

Sensor grip system for FT 3000 CH

with single clamp (replaces standard grips)

For exact measurement of completed cycles to failure of the sample. Each position in the sample holder has a variable clamp for individual sample mounting; with an integrated, non-contact tension, precision sample sensor for exact detection of the cycle at sample failure. The time of failure (in cycles, minutes or seconds) is automatically transferred to the software and stored.