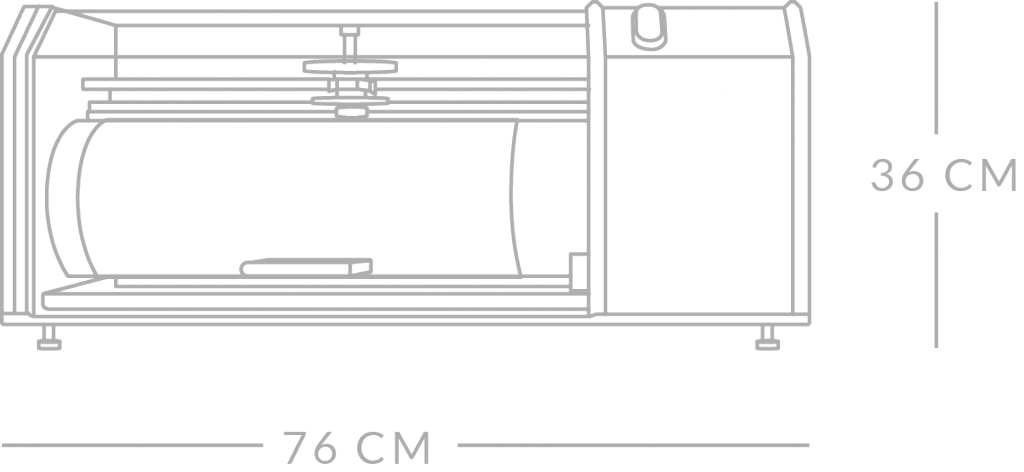

The MonTech ABR 3000 Abrasion tester is a tear testing instrument for determination of the resistance of elastomers in regards to the frictional loss of a rotating or fixed specimen.

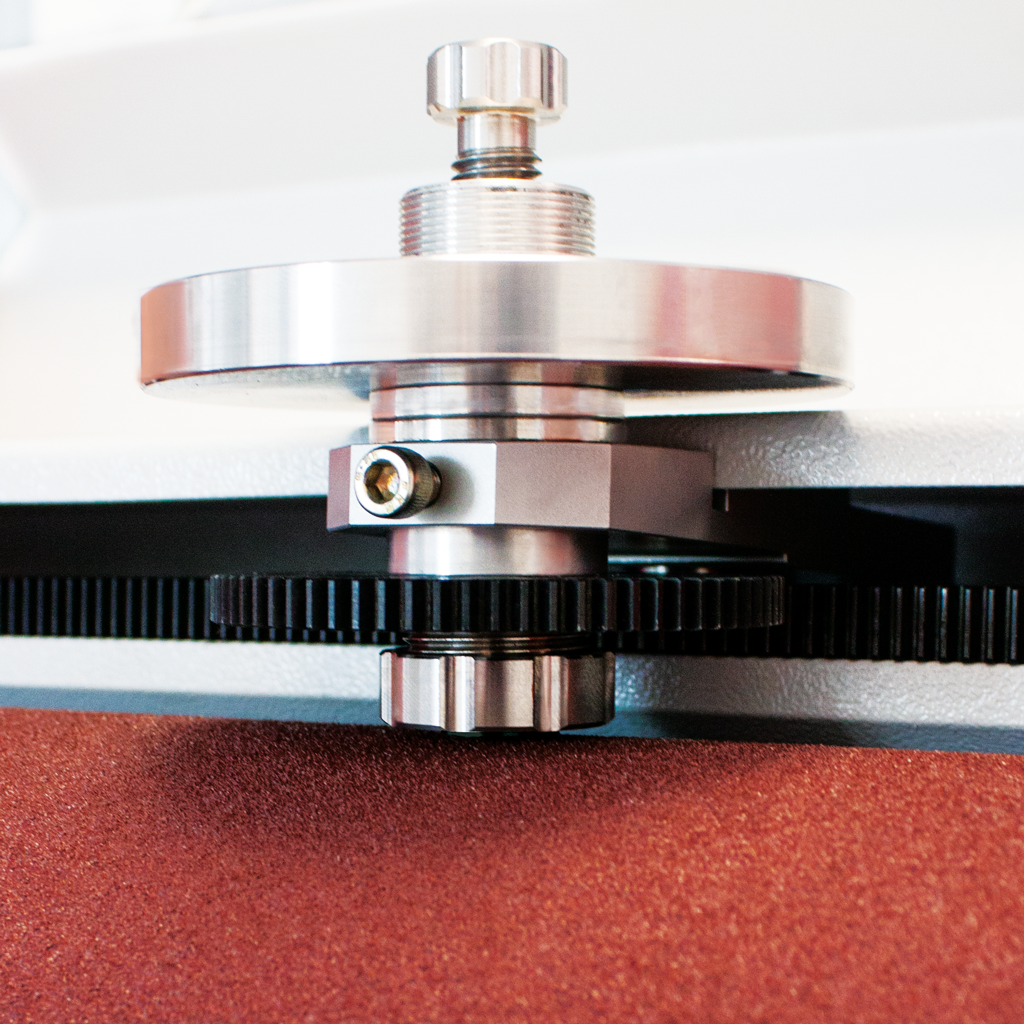

The working area is protected with translucent cover and protective safety switch. The specimen holder has a integrated dead weight of 2,5 N. Additional loading weights of 2,5 N and 5,0 N are supplied as standard accessories.

Test Procedure

1. After determination of the abrasiveness of the abrasion sheet, the instrument is ready for testing. Samples can easily be drilled out of a rubber sheet or final product with the optional circular cutting knife. Typically tests are performed at ambient temperature of 23 ± 5°C or with the optional drum heating at elevated temperatures.

2. Initially the weight of the test specimen is measured

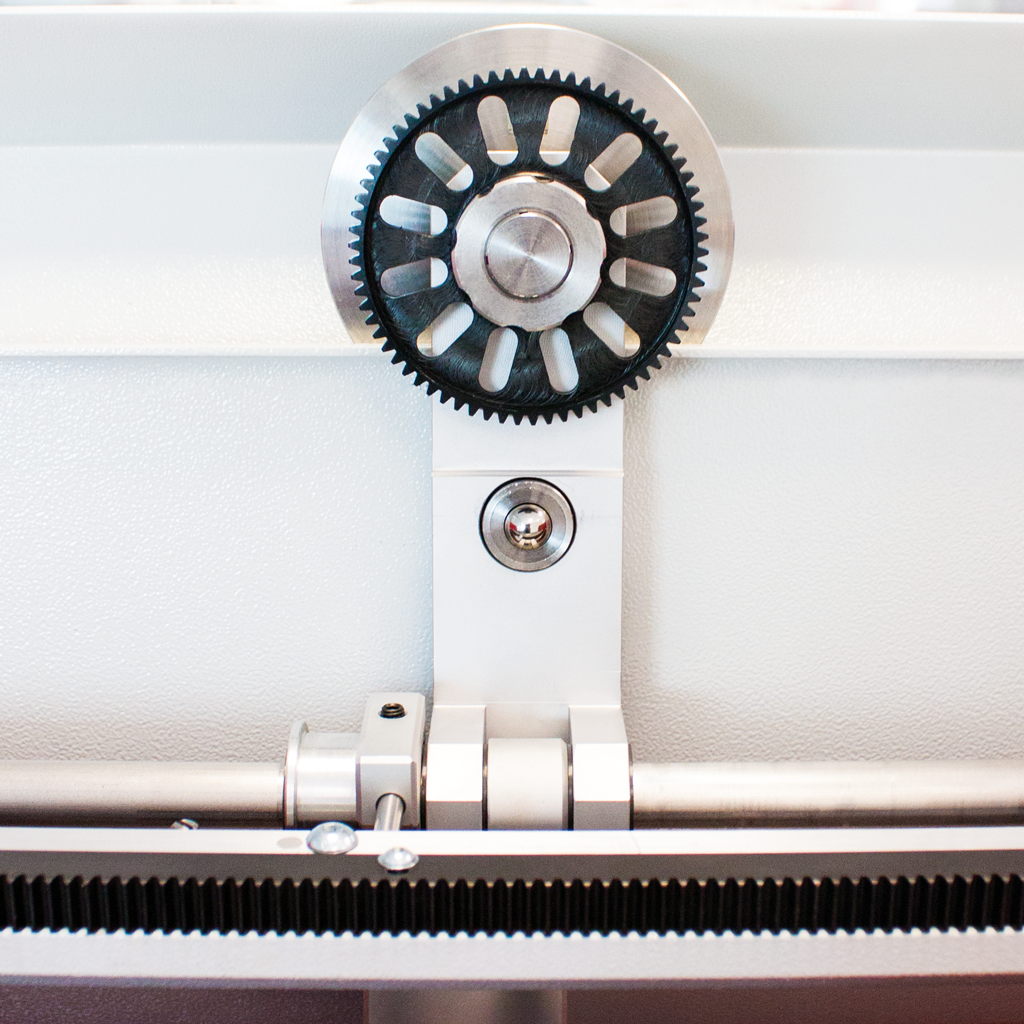

3. Afterwards the sample is mounted into the sample holder, the desired abrasion distance is set and the load weights are applied. The instrument cover is closed and the test is started by a simple click on the start button. The rotation of the drum will start and the specimen will be moved over the abrasive sheet. Once the pre-set abrasion distance is reached, the instrument will stop automatically.

4. After the test run is finished, the sample is removed from the sample holder and the weight of the sample after abrading is measured.

5. For calculation of the abrasion, the mass loss (average value of 3 to 10 single values) is converted to the loss of volume by help of the density and corrected for the deviation of the abrasiveness of the abrasion sheet from the set value of abrasiveness. Formula: Abrasion= mass lost x 200 specific weight x abrasiveness