Static and dynamic testing

The D-MDR 3000 is designed for measuring the viscoelastic properties of polymers and elastomeric compounds before, during and after cure. The acquired data gives exact information about advanced material properties, processability, cure characteristics, cure speed, behavior of the compound at the after-cure and final compound dynamic mechanical properties, with an unlimited amount of testing steps and subroutines.

The D-MDR 3000 is the universal dynamic Moving Die Rheometer, providing the highest testing flexibility for static as well as dynamic testing applications for all kinds of rubber, rubber-like, curing or crosslinking materials. This includes, of course, all kinds of rubber materials filled with carbon black, silica or any other type of organic or inorganic filler, as well as TPE, TPV, LSR, and Composite Materials such as Prepregs, Polyolefins, Glues, Gelatine, …

Utilizing a unique, patented, wearless direct drive design with digital drive and control technology, the D-MDR 3000 can cover almost every possible test condition in any combination, with shear rates up to 500 sec-1. Temperature in the dies is precisely controlled and the unique direct double channel forced air cooling system not only enables rapid cooling to the setpoint but also allows non-isothermal testing and integrated friction heat compensation essential to high-strain testing.

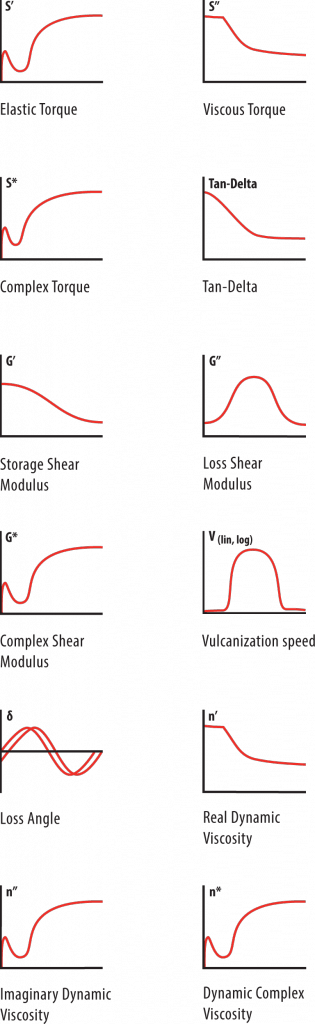

High precision torque and force measurements, in conjunction with the high resolution motor feedback, guarantee the most precise and accurate torque readings to derive elastic modulus, measured as in-phase stress (S‘), and viscosity, measured as out-of-phase stress (S‘‘), as well as loss angle and tan-delta.

Based on this fundamental measurement data, modulus (G), dynamic viscosity (η), Compliance (J), Tensile Modulus (E), Compliance under extension/compression (D), Spring rate (K) and Damping coefficient (C) are calculated.