Advanced Dynamic Moving Die Rheometer

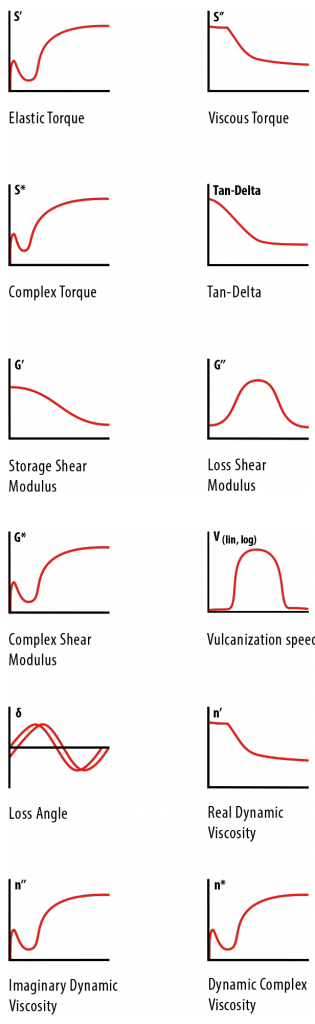

The D-RPA 3000 is designed for measuring the viscoelastic properties of polymers and elastomeric compounds before, during and after cure. The acquired data gives exact information about the processability, cure characteristics, cure speed, and behavior of the compound at the after-cure.

The D-RPA 3000 fulfills the complete range of all test requirements; Polymers, raw materials, basic, finished and cured compounds can all be characterized. Besides the cure properties, cure characteristics and processability can all be determined and evaluated.

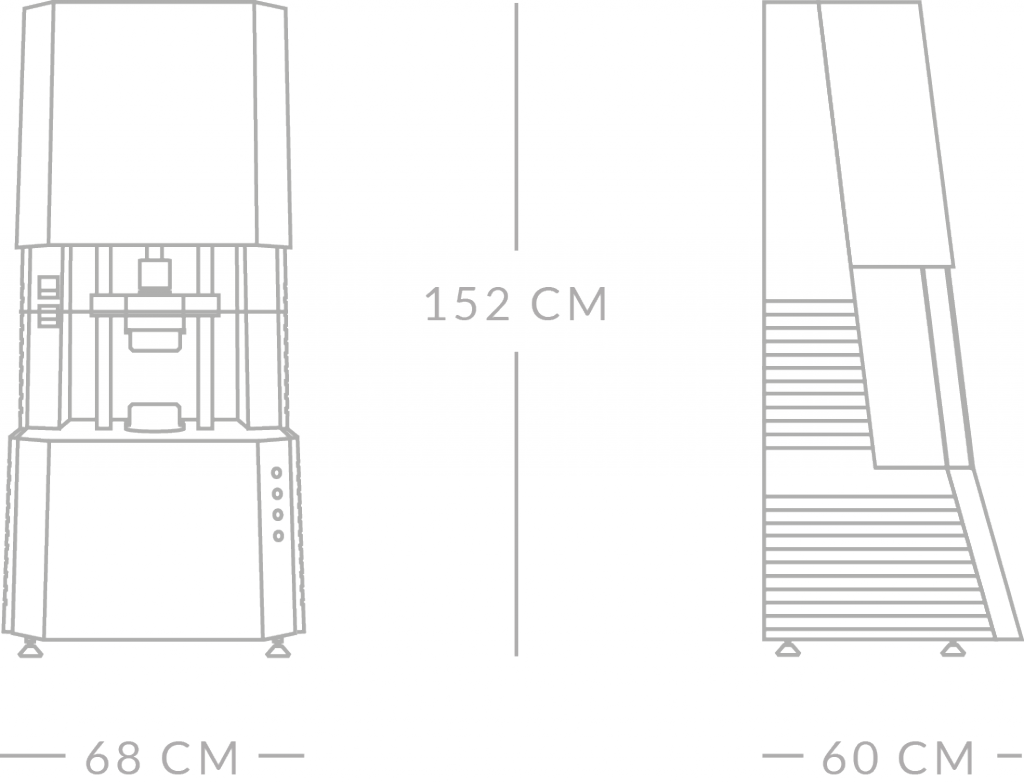

The D-RPA 3000 is the state-of-the-art machine for dynamic testing purposes. The machine can be fitted with several unique options such as variable die gap, low-temperature cooling, and high speed data acquisition – providing the highest frequency-strain combination available on the market.

The high flexibility of the D-RPA 3000 allows the user to program and execute arbitrary test sequences with the MonControl Analyses Software. Each dynamic test sequence can include an unlimited number of the following substeps: timed tests, isothermal tests, non-isothermal tests, amplitude sweeps, frequency sweeps, temperature sweeps, shear rate sweeps, relaxations, retardations, hysteresis and tension tests. Of course, any combination of these sub-tests are possible – with or without an initial strain, as well as strain or stress controlled.

Equipped with single test – multi subtest test procedure programming with up to 1000 sub-programs as well as an unbeaten shear rate range of up to 100 sec-1 – the D-RPA 3000 is truly the most flexible and dynamic multi function Rheometer in the market.

Completely closed, directly heated, biconical test chamber system

entirely made of high-strength stainless steel, precision ground and hardened, significantly reducing sample slippage for highest dynamic test ranges and most accurate torque, modulus and viscosity readings.