Computer aided, advanced digital reflected light microscopy brought to the next level

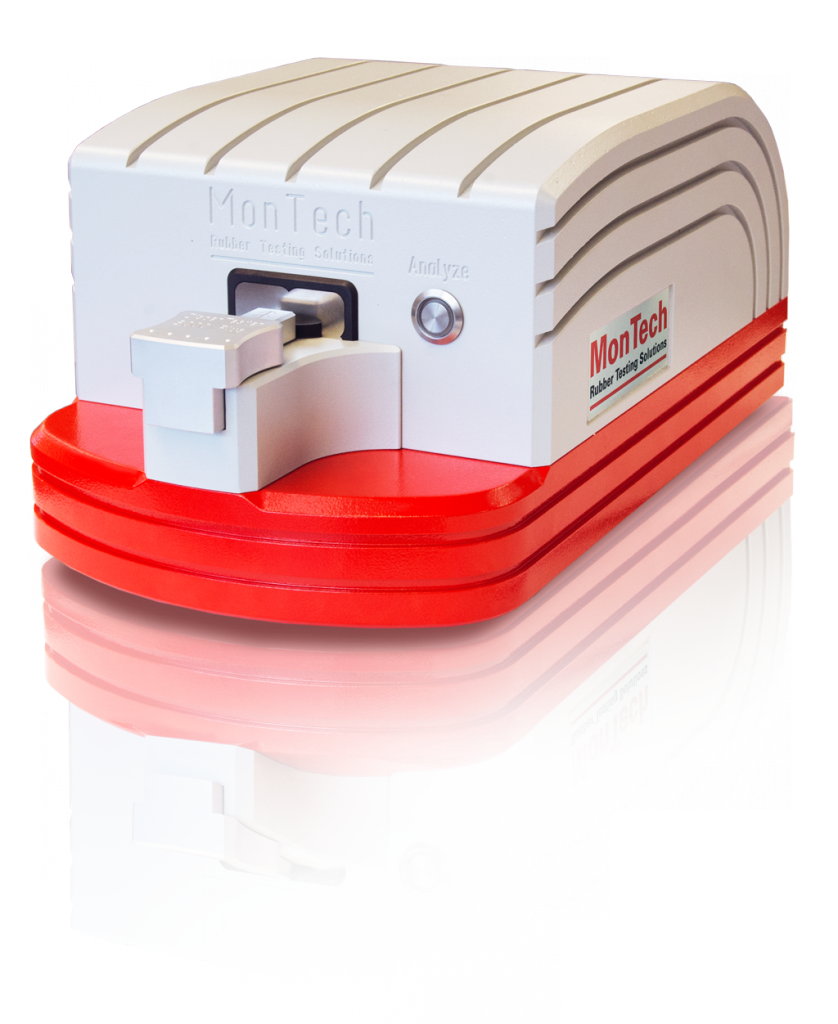

The DisperTester 3000 is the most easy to use instrument for filler dispersion analysis; providing superior compliance, reproducibility and repeatability.

The DisperTester provides accurate, repeatable results in seconds for both vulcanized and uncured rubber compounds that are applicable to the process, allowing quick and easy testing of dispersion compared to other optical techniques which often take hours to perform (less than 2 minutes with sample preparation). The DisperTester 3000 is equipped with cutting edge digital image processing to automatically determine dispersion ratings, filler distributions and agglomerate sizes. Up to 5 individual readings can be taken in order to precisely evaluate the dispersion and detect possible variations along the surface of the sample.

To increase testing possibilities even further, the MonDispersion software features variable brightness, contrast and exposure, as well as focus control for every type of test material, allowing colored or even white samples to be tested.

The DisperTester 3000 system includes built-in reference scales and can be used for all filler types including Carbon Black, Silica and natural inorganic materials with fully automatic calculation of X value, Y value, Z %, Dispersion %, White area %, … in accordance with international standards. All data is processed automatically by the MonDispersion software. Agglomerates are automatically highlighted and can even be manually measured by their diameter and normalized area. Test results are stored in an SQL database. PDF reports along with distribution spreadsheets and histograms are created and images are stored into an image database in a high-resolution JPEG format. Of course custom reference scales can be easily added by the user at any time.

The determination of fi ller dispersion in technical rubber goods and tire compounds is of great importance to the industry.

Dispersion quality has a direct impact on fi nal product properties and is therefore widely used as a quality control parameter.