Static testing

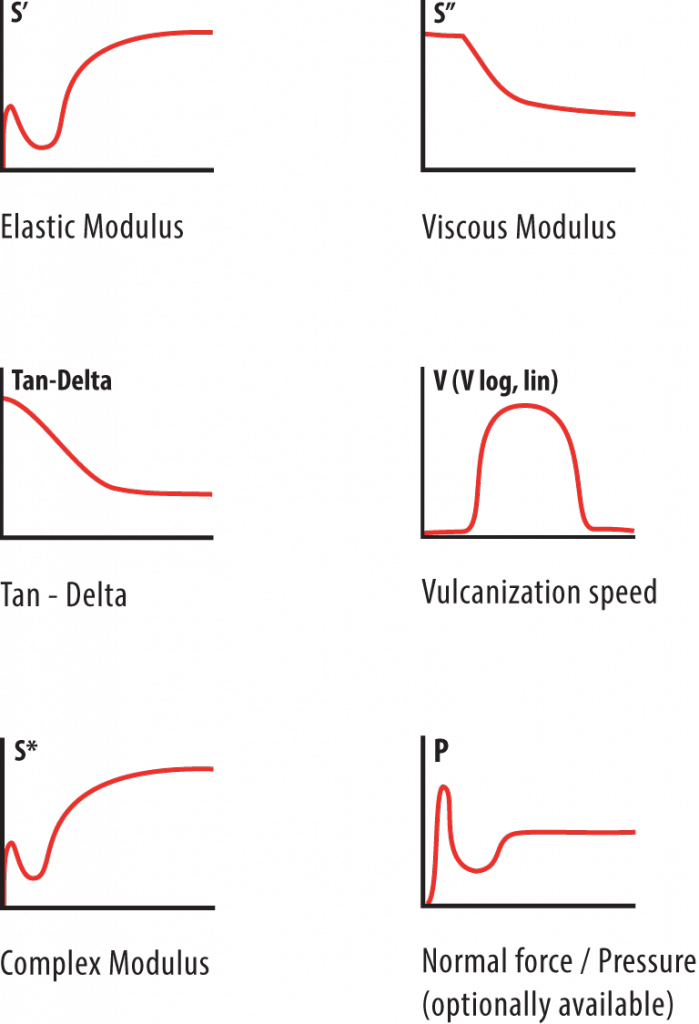

The MDR 3000 is the industry standard for measuring the viscoelastic properties of polymers and elastomeric compounds before, during and after cure. The acquired data is gives advanced information about processability, cure characteristics, cure speed, as well as the behavior of the compound after-cure at fixed, user selectable strain rates.

The instrument comes in the unique MonTech Series 3000 loadframe – industrial proof, fanless and ultra-rugged even for toughest production environments.

The reaction torque is measured by a high resolution, digital strain gauge assembly with integrated temperature compensation, making the MDR 3000 the most accurate and precise Moving Die Rheometer for static testing. Optionally, the instrument can be equipped with a combined torque / normal force sensor to assess blowing or sponging reactions of the tested material. For increased productivity and throughput, various types of highly reliable automation systems are also available.

Of course the MDR 3000 can be easily upgraded at a later stage to an MDR 3000 Professional to not only be able to run static but also dynamic test sequences.

Unique direct drive system

The instrument utilizes a direct, high-precision, gearless torque drive system mounted

directly to the lower die assembly. Therefore, the oscillation angle can be directly changed in the MonControl software, making the instrument capable of always measuring materials in the optimal strain range. This feature significantly reduces signal noise, improving the accuracy of testing results. With this fully digital drive system, no mechanical strain adjustments are needed and the motor positioning is monitored and recorded throughout the test.