Static testing

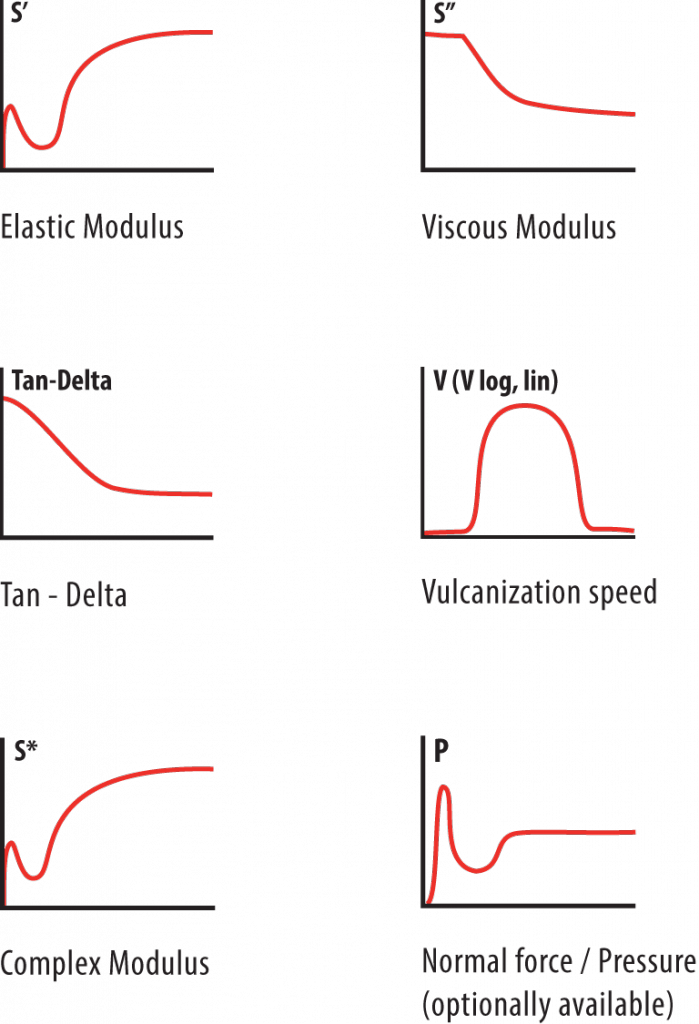

The MDR 3000 Basic is the easiest to operate and most cost-effective way to determine viscoelastic properties of polymers and rubber compounds before, during and after cure. The acquired data gives exact information about processability, cure characteristics, cure speed and the behavior of the compound after-cure, as well as optional pressure measurement for sponge rubber compounds.

The MDR 3000 Basic comes as a complete and ready-to-test set consisting of the Rheometer itself, an external Personal Computer with the latest Windows Operating System, TFT screen, keyboard and mouse, as well as a printer.

Like every MonTech Rheometer, the MDR 3000 Basic also features an Ethernet Interface and can therefore be directly integrated in any customer’s factory network, guaranteeing the most stable data transfer and communication in any laboratory or factory environment, allowing data access at the instrument and from remote and office workstations, creating a digital process chain and integrated workflow based on a digital data repository, eliminating the need of result printing after each test series.

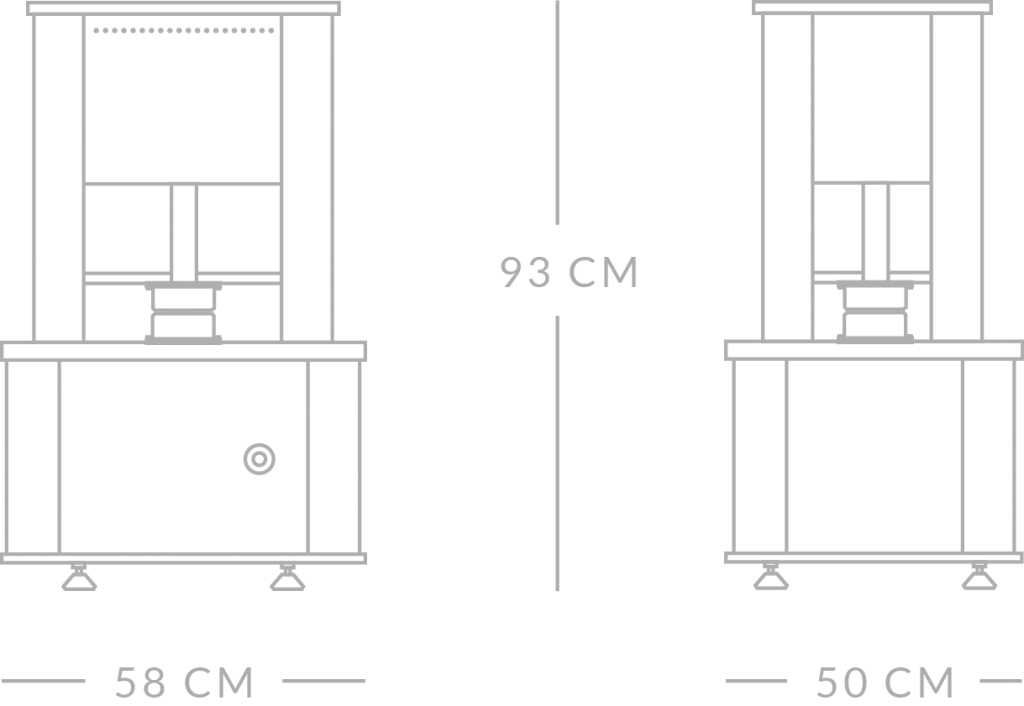

Designed as a table top instrument utilizing only minimal benchspace, the MonTech MDR 3000 Basic is synonymous with a reliable but easy and efficient testing operation. The instrument is equipped with the latest PLC-based control and data acquisition electronics, ensuring the highest data acquisition precision and reliability, along with superior temperature control – improving overall data significance and laboratory efficiency. The instrument comes with the MonControl Analysis software for test configuration management, data recording, automated Pass/Fail testing, processing of historical data as well as online statistical process control (SPC), having more than 3500 different datapoints available for selection. With an optional 5“ instrument touch-control panel, the instrument can even be conveniently operated in stand-alone mode by directly displaying and printing the most essential datapoints – including the possibility to save and archive test data on a USB flashdrive.

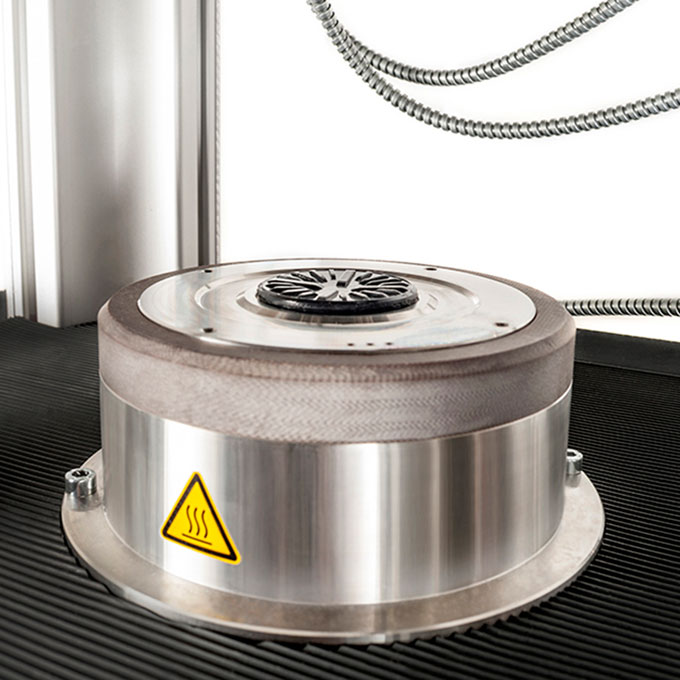

Completely closed, rotor-less, sealed, biconical test chamber system

Entirely made from stainless steel, precision machined, hardened and ground to utmost precision for highest durability and testing accuracy. The lower die is directly connected to the central shaft and drive system. All these parts and components are also made from solid stainless steel, making the MDR 3000 Basic a cost-efficient, long-lasting and safe investment. The upper die is attached to the reaction torque measurement for immediate recording of the material feedback at the highest precision.

The MDR 3000 Basic features an extremely stiff, ultra-rugged loadframe paired with a unique, column-guide-free, accessible testing area along with the most simple singlebutton operation and integrated multi-color status bar making this instrument truly the most reliable testing system for quality control purposes not only in the laboratory, but also directly in the production area. Of course various different automation options for increasing testing productivity are available and can be fitted to the instrument at any time.