Static and dynamic testing

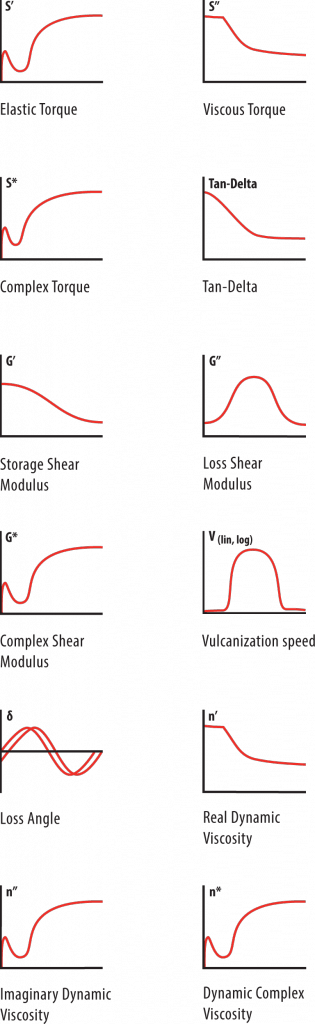

The MDR 3000 Professional is designed for measuring the viscoelastic properties of polymers and elastomeric compounds before, during and after cure. The acquired data gives exact information about advanced material properties, processability, cure characteristics, cure speed, and the behavior of the compound at the after-cure, as well as final compound dynamic mechanical properties.

The MDR 3000 Professional is a unique hybrid testing system; it can be operated in static testing (MDR) mode and with a single click in the MonControl Software, be switched over into dynamic testing (RPA) operation mode. This provides the highest possible flexibility to the user as the MDR 3000 Professional can cover everyday routine QC tasks by working like a normal static Moving Die Rheometer at highest accuracy, repeatability and reproducibility while offering full Rubber Process Analyzer testing capabilities for even complex R&D testing, allowing the user to program, execute and evaluate arbitrary test sequences with the included MonControl Software.

The instrument is equipped with MonTech‘s unique, patented direct precision drive system, offering variable oscillation amplitude and frequency along with precision temperature control, enabling testing according to almost every DIN / ISO and ASTM test standard in reference to Moving Die Rheometers and Rubber Process Analyzers.

Due to the rugged and flexible construction and various options such as cooling and automation, this device can be used for extended quality control and production monitoring purposes not only in the laboratory, but also directly on the shopfloor.