Automatic Schob pendulum impact elasticity tester for elastomers and foams.

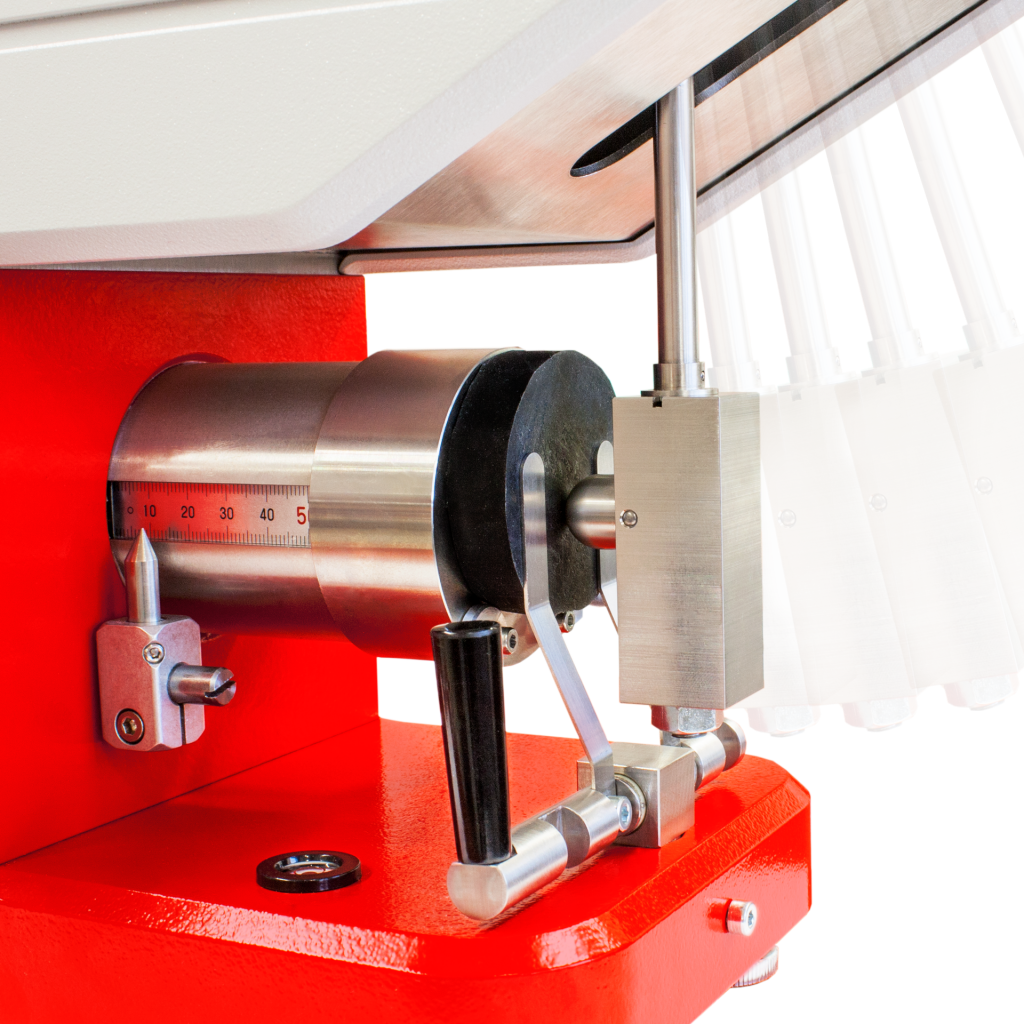

MonTechs RB 3000 resilience tester features a rigid design with all main components integrated into the machine frame – the electronics with 5” touchscreen display, data interfaces as well as the entire mechanical system which is precisely manufactured from high strength and aluminum. The pendulum mechanism features a 15mm diameter hammer fin and is connected via the pendulum arm to a virtually frictionless air bearing system connectedt to a high resolution non-contact encoder system guaranteeing highest precision in pendulum angle measurement.

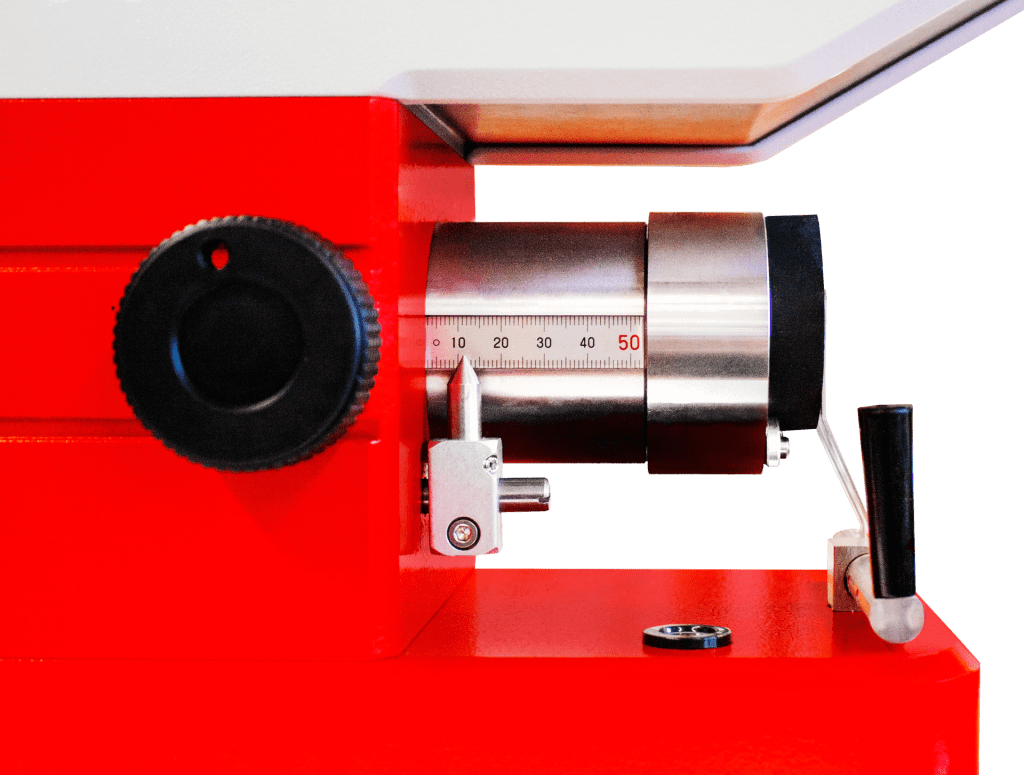

A fully integrated spindle with adjustment gauge and clamping allows a quick and easy setup of the test specimen thickness so that testing can start right away. The RB 3000 is equipped with a motorized pendulum release and return allowing a fully automated test sequence without any user interference.

Once the operator presses the start button on the multi-language touch-control panel, the instrument executes the selected test sequence automatically – including up to three pre-hits and three test hits. Once the test sequence is completed the test results are automatically displayed on the built in 5” touchscreen as well as also the median is calculated.

The instrument has been designed keeping safety, comfort but also ease of use in mind:

- Simplified touchscreen operation, menu guided with various comfort functions such as different test modes, parking and service functions

- The test sequence can only be started once a sample has been placed on the anvil in order to protect hammer and anvil against any kind of damage

- Automatic detection of incorrect placed specimens

- Fully automated test sequence with motorized pendulum release and return eliminating almost any operator influence

- Integrated calibration routines allow the user to measure, calibrate and compensate the pendulum friction

- Interchangeable hammers, fins and anvil plates for various applications and sample types

- Easy setup with levelling feet and integrated spirit level and completely maintenance free mechanical system

- With the optional temperature control units a temperature tolerance can be set, allowing a test only to be started once the set temperature is reached