High-end Mooney Viscometer

The Variable Mooney Viscometer V-MV 3000 brings traditional Mooney Viscosity, Scorch and Stress Relaxation testing to the next level. Besides the ultra-rigid test frame, the instrument incorporates the latest direct servo drive technology and superior design for unbeaten data accuracy and test result precision.

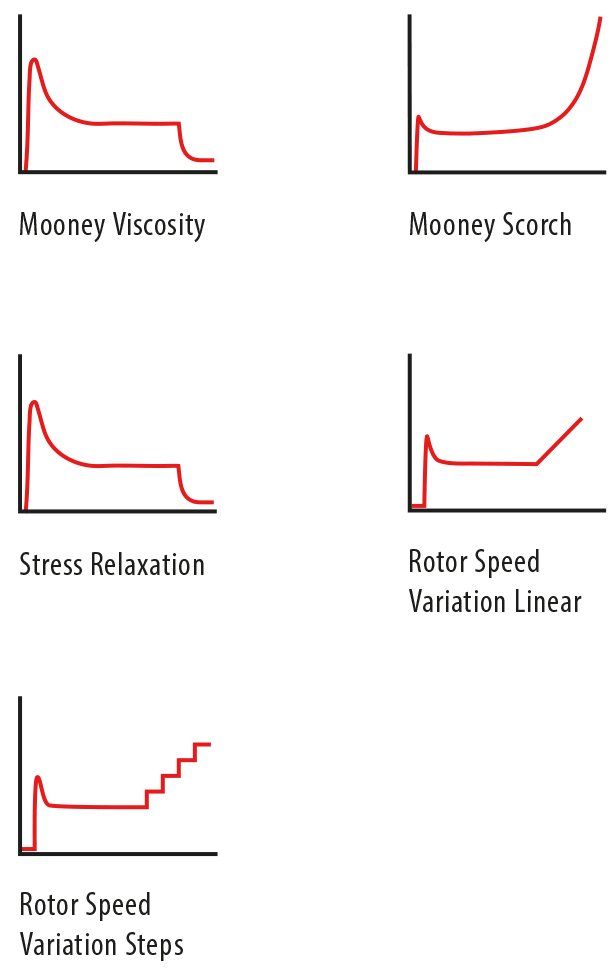

In addition to static Mooney Viscometer testing at fixed rotor speeds under isothermal conditions according to international standards, the Variable speed Mooney Viscometer V-MV 3000 is further capable of running test sequences at variable rotor speeds as well as fully dynamic tests including speed steps, ramps and multi-step relaxation, all this with simultaneous temperature profiles and optional cooling of the sample in the die cavity to as low as +10ĀčC, making the V-MV 3000 not only ideal for polymers and rubber compounds, but also silicone, latex and epoxy resin testing.

This functionality efficiently provides very useful additional information on the test material at the highest accuracy. For example, materials showing similar static viscosities at 2rpm can now be tested at variable shear rates and temperatures.

From these results, polymer specialists can gain a much better understanding of polymer and rubber behavior regarding branching, molecular weight distribution, average molecular weight as well as shear thinning.

The instrument is equipped with MonControl Software and special block programming features to allow an unlimited number of rotor speeds and test temperatures per test – of course in any combination.